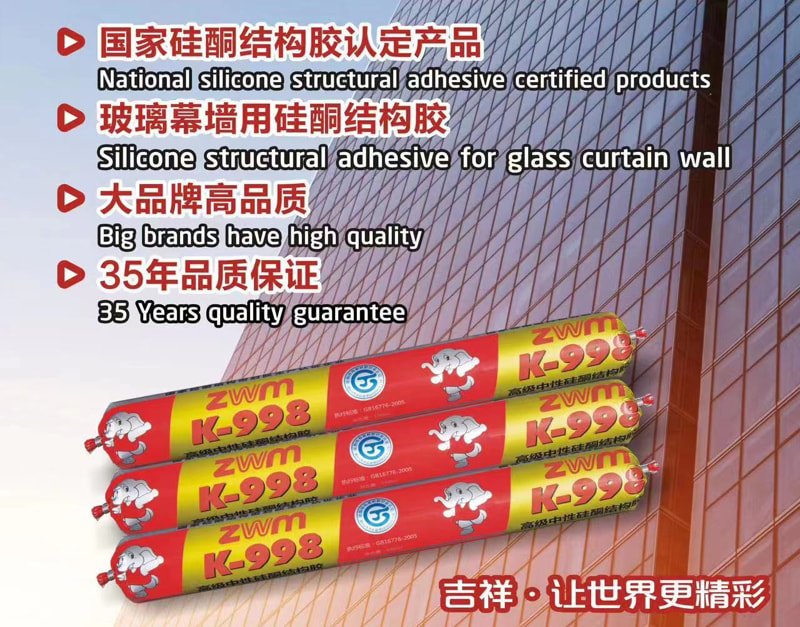

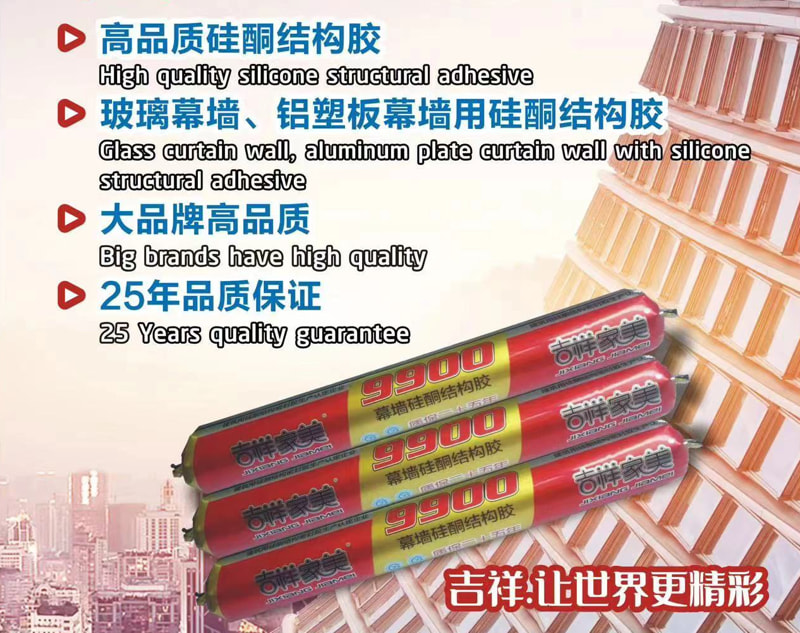

Internal content: polysiloxane: 60% silicon dioxide and inorganic filler: 31%

Product description: This product is a one component, neutral curing, dealcoholized curtain wall structural adhesive. Available in black, gray, porcelain white (or the color required by the user).

Product use:

1. Structural assembly of glass, metal, stone, curtain wall, etc.

2. Many other architectural and industrial uses.

Restricted use: This product is not applicable to places that are continuously immersed in water or wet all the year round, all materials that will exude grease, plasticizer or solvent, and airtight places. The user must decide the applicability of the product by himself. The company is not responsible for any loss caused by accident.

Product characteristics:

1. Neutral curing, non corrosive.

2. Excellent weather resistance, UV resistance, ozone resistance and water resistance.

3. Strong adhesion to most building materials requires that the construction surface must be clean and free of oil stain.

4. When the surface temperature of the material is lower than 5 ℃ or higher than 35 ℃, it is not suitable for construction. After curing, the temperature between - 50 ℃ and 100 ℃ remains essentially unchanged.

[Note]: Do not let children touch. If the eyes directly contact the uncured adhesive, wash them with plenty of water and ask a doctor for help.

Shelf life: 8 months

Specifications: 300ml, 500ml (soft package), 600ml (soft package)

Responsibility statement:

The company guarantees that the products manufactured by it strictly comply with the national quality standards. However, based on the differences in construction conditions (including materials, construction methods, climate, etc.), pre-test should be carried out before use and the applicability of the products should be independently determined to meet the construction requirements. The company is responsible for the quality of the products properly stored and used within the validity period. Within this scope, if the products do not meet the quality requirements, customers can replace the products. In addition, the Company shall not assume any other direct or indirect responsibility. The company provides technical support for products, and can contact the dealer or the company.

Internal content: polysiloxane: 60% silicon dioxide and inorganic filler: 31%

Product description: This product is a one component, neutral curing, dealcoholized curtain wall structural adhesive. Available in black, gray, porcelain white (or the color required by the user).

Product use:

1. Structural assembly of glass, metal, stone, curtain wall, etc.

2. Many other architectural and industrial uses.

Restricted use: This product is not applicable to places that are continuously immersed in water or wet all the year round, all materials that will exude grease, plasticizer or solvent, and airtight places. The user must decide the applicability of the product by himself. The company is not responsible for any loss caused by accident.

Product characteristics:

1. Neutral curing, non corrosive.

2. Excellent weather resistance, UV resistance, ozone resistance and water resistance.

3. Strong adhesion to most building materials requires that the construction surface must be clean and free of oil stain.

4. When the surface temperature of the material is lower than 5 ℃ or higher than 35 ℃, it is not suitable for construction. After curing, the temperature between - 50 ℃ and 100 ℃ remains essentially unchanged.

[Note]: Do not let children touch. If the eyes directly contact the uncured adhesive, wash them with plenty of water and ask a doctor for help.

Shelf life: 8 months

Specifications: 300ml, 500ml (soft package), 600ml (soft package)

Responsibility statement:

The company guarantees that the products manufactured by it strictly comply with the national quality standards. However, based on the differences in construction conditions (including materials, construction methods, climate, etc.), pre-test should be carried out before use and the applicability of the products should be independently determined to meet the construction requirements. The company is responsible for the quality of the products properly stored and used within the validity period. Within this scope, if the products do not meet the quality requirements, customers can replace the products. In addition, the Company shall not assume any other direct or indirect responsibility. The company provides technical support for products, and can contact the dealer or the company.

Internal content: polysiloxane: 49% plasticizer (oil): 32% silicon dioxide: 13%

Product description: This product is a kind of acid glue with wide use and strong durability, which is used for glass sealing and building materials.

Product application: assembly of glass, aluminum alloy, ceramics, glass fiber, plastic steel, non oil wood, etc. For powder spraying of aluminum alloy, the wax coating must be completely removed with solvent.

Restrictions on use:

1. It cannot be used as structural adhesive;

2. This product is acid solidified and corrosive to porous stone, zinc and iron materials;

3. It shall not be used on oily or seeping surfaces.

usage method:

1. One component, acetic acid, room temperature curing silicone sealant, easy to use;

2. It has good adhesive property;

3. Trim and remove the adhesive tape before curing.

Product characteristics:

1. One component, acetic acid. Room temperature curing silicone sealant, easy to use;

2. It has good adhesive property;

3. Available in transparent, porcelain white, silver gray, black and other colors, and other colors can be provided according to customer needs.

[Precautions]:

1. The construction site shall be ventilated to avoid irritation or allergy to eyes and skin. If it accidentally enters the eyes, it shall be immediately cleaned with water or consult a doctor to avoid children's contact;

2. Store in a cool and dry place. The best environment is: temperature 25 ℃, humidity 50%. If the deviation from the above environment is too large, it will affect the product's shelf life, service life and normal environment.

Shelf life: 8 months

Specification: 260ml, 300ml

Product description: This product adopts the latest formula, uses polychloroprene, and is a replacement product produced by a special process. It has high bonding strength, fast drying speed, easy painting, good durability, good cold resistance and moisture resistance, even glue without precipitation, excellent quality and superior quality.

Application: It is applicable to the self adhesion and mutual adhesion of aluminum plastic plate, wood, fireproof plate, paint free plate, bamboo plate, Baoli plate, PVC plate, sponge, ceramics, carpet material, hard plastic plate, rubber, general leather, stainless steel plate and various metal materials.

Usage: The two surfaces of the adherend must be clean and dry, and oil stain is strictly prohibited; Evenly brush the glue solution on the two bonding surfaces (shake well when using), which can be kept constant (180-200g/m 2). Leave it in the air at room temperature for 5-15 minutes. In a cold and humid environment, extend the time appropriately. After the glue solution is in a dry film shape (it is better not to stick hands), it can be bonded. The adhesive shall be gradually bonded from one side to the other, and then pressure shall be applied from the middle to the edge to remove air and prevent bubbles. In order to achieve a better bonding effect, 2kg force shall be applied to roll up or knock 2-3 times after bonding, and the best effect shall be achieved after 24 hours at room temperature.

[Precautions]:

1. This product contains volatile solvent. Keep the air unblocked when using it. Do not approach open fire, swallow it, or let children touch it.

2. The moisture content of plates shall not be higher than 5%.

3. This product should not be used in direct sunlight or places where the temperature exceeds 120 ℃. (Suitable temperature - 10 ℃ to 120 ℃)

4. New materials that have not been used should be used in a small area before use, and can only be used after the product quality is approved.

5. If dilution is required, it can be diluted with the company's special thinner.

6. Please follow the manufacturer's instructions for safe use. Our company will not be responsible for any accident caused by unauthorized use.

Shelf life: 12 months

Specifications: 18L, 3L

Executive standard: GB18583-2001 QNAHH2-2006 Limit of harmful substances in rubber solvent adhesive:

Product description: This product adopts the latest formula, uses new polymer materials, and is a new generation of products produced by special processes. It has high bonding strength, fast drying speed, easy painting, good durability, good cold resistance and moisture resistance, even glue without precipitation, excellent quality and superior quality.

Application: It is applicable to the self adhesion and mutual adhesion of aluminum plastic plate, wood, fireproof plate, paint free plate, bamboo plate, Baoli plate, PVC plate, sponge, ceramics, carpet material, hard plastic plate, rubber, general leather, stainless steel plate and various metal materials.

Usage: The two surfaces of the adherend must be clean and dry, and oil stain is strictly prohibited; Evenly brush the glue solution on the two bonding surfaces (shake well when using), which can be kept constant (180-230g/m 2). Leave it in the air at room temperature for 5-30 minutes. In a cold and damp environment, extend the time appropriately. After the glue solution is in a dry film shape (it is better not to stick hands), it can be bonded. The adhesive shall be gradually bonded from one side to the other, and then pressure shall be applied from the middle to the edge to remove air and prevent bubbles. In order to achieve a better bonding effect, 2kg force shall be applied to roll up or knock 2-3 times after bonding, and the best effect shall be achieved after 24 hours at room temperature.

[Precautions]:

1. This product contains volatile solvent. Keep the air unblocked when using it. Do not approach open fire, swallow it, or let children touch it.

2. The moisture content of plates shall not be higher than 5%.

3. This product should not be used in direct sunlight or places where the temperature exceeds 60 ℃. (Suitable temperature - 20 ℃ to 60 ℃)

4. New materials that have not been used should be used in a small area before use, and can only be used after the product quality is approved.

5. If dilution is required, it can be diluted with the company's special thinner.

6. Please follow the manufacturer's instructions for safe use. Our company will not be responsible for any accident caused by unauthorized use.

Shelf life: 12 months

Specifications: 18L, 3L

Executive standard: GB18583-2001 Q/VAHH2-2006 Limit of harmful substances in rubber solvent adhesive:

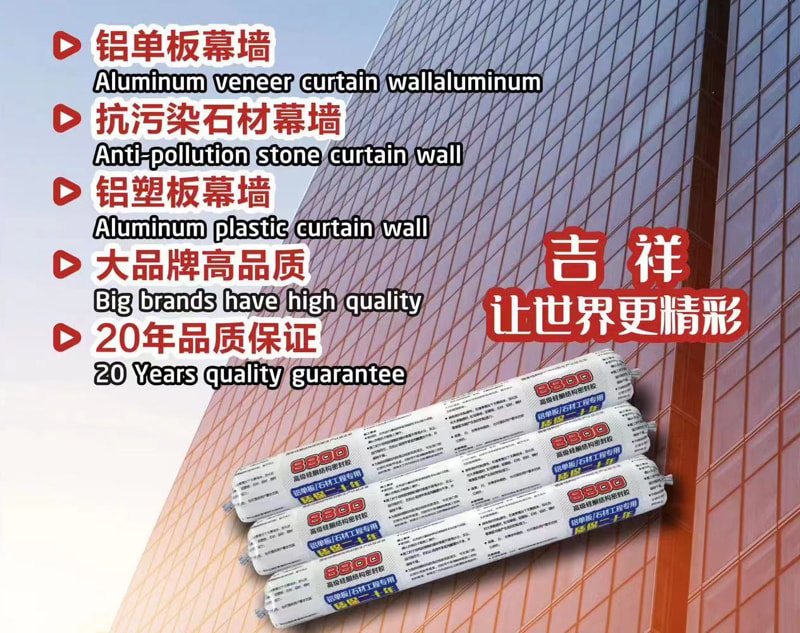

Internal content: polysiloxane: 43% plasticizer (oil): 10% silicon dioxide and inorganic filler: 40%

Product description: This product is a one component, neutral curing, dealcoholized, low modulus silicone sealant. It has good elasticity and flexibility.

Product use:

1. The joint of glass daylighting roof shall be sealed.

2. Joints of organic glass, aluminum plastic plate, sunlight plate and other materials shall be sealed.

3. Coated glass and glass are bonded and sealed.

Restricted use: This product is not applicable to structural glass assembly engineering, places that are continuously immersed in water or wet all the year round, all materials that will exude grease, plasticizer or solvent, and airtight places. The user must decide the applicability of the product by himself. The company is not responsible for any loss caused by accident.

Product characteristics:

1. Neutral curing, non corrosive.

2. Excellent weather resistance, UV resistance, ozone resistance and water resistance.

3. No primer is required, which can produce strong adhesion to most building materials, but the surface must be clean and free of oil stain.

4. When the surface temperature of the material is lower than 5 ℃ or higher than 35 ℃, it is not suitable for construction. After curing, the temperature between - 50 ℃ and 100 ℃ remains essentially unchanged.

Shelf life: 8 months

Specifications: 260ml, 300ml, 500ml (soft package), 600ml (soft package)

Attention: Do not let children touch it. If the eyes directly contact the uncured adhesive, wash them with plenty of water and ask a doctor for help.

Responsibility statement:

The company guarantees that the products manufactured by it strictly comply with the national quality standards. However, based on the differences in construction conditions (including materials, construction methods, climate, etc.), pre-test should be carried out before use and the applicability of the products should be independently determined to meet the construction requirements. The company is responsible for the quality of the products properly stored and used within the validity period. Within this scope, if the products do not meet the quality requirements, customers can replace the products. In addition, the Company shall not assume any other direct or indirect responsibility. The company provides technical support for products, and can contact the dealer or the company.

Product characteristics:

1. One component, acid, room temperature curing silicone sealant, easy to use;

2. Good adhesion;

3. Available in transparent, porcelain white, silver gray, black and other colors, and other colors can be provided according to customer needs.

Product use:

1. Sealing of glass, doors and windows;

2. Sealing of various decorations

usage method:

1. Clean the surface of the material to be bonded with solvent or other methods;

2. Stick adhesive tape on the parts to be protected;

3. Trim and remove the adhesive tape before curing.

Restrictions on use:

1. It cannot be used as structural adhesive;

2. This product is acid solidified and corrosive to porous stone, zinc and iron materials;

3. It shall not be used on oily or seeping surfaces. It is not suitable to completely isolate the air before curing.

matters needing attention:

1. Keep the construction site ventilated to avoid irritation or allergy to eyes and skin. If it accidentally enters the eyes, wash it with clean water or seek medical advice immediately to avoid children's contact;

2. Store in a cool and dry place. The best environment is 25 ℃ temperature and 50% humidity. If the deviation from the above environment is too large, the storage life and service life of the product will be affected.

Shelf life: 8 months

Specification: 260ml, 300ml

[Note]: Do not let children touch. If the eyes directly contact the uncured adhesive, wash them with plenty of water and ask a doctor for help.

Responsibility statement:

The company guarantees that the products manufactured by it strictly comply with the national quality standards. However, based on the differences in construction conditions (including materials, construction methods, climate, etc.), pre-test should be carried out before use and the applicability of the products should be independently determined to meet the construction requirements. The company is responsible for the quality of the products properly stored and used within the validity period. Within this scope, if the products do not meet the quality requirements, customers can replace the products. In addition, the Company shall not assume any other direct or indirect responsibility. The company provides technical support for products, and can contact the dealer or the company.

Product description: This product adopts the latest formula, uses polychloroprene, and is a replacement product produced by a special process. It has high bonding strength, fast drying speed, easy painting, good durability, good cold resistance and moisture resistance, even glue without precipitation, excellent quality and superior quality.

Application: It is applicable to the self adhesion and mutual adhesion of aluminum plastic plate, wood, fireproof plate, paint free plate, bamboo plate, Baoli plate, PVC plate, sponge, ceramics, carpet material, hard plastic plate, rubber, general leather, stainless steel plate and various metal materials.

Usage: The two surfaces of the adherend must be clean and dry, and oil stain is strictly prohibited; Evenly brush the glue solution on the two bonding surfaces (shake well when using), which can be kept constant (180-200g/m 2). Leave it in the air at room temperature for 5-15 minutes. In a cold and damp environment, extend the time appropriately. After the glue solution is in a dry film shape (it is better not to stick hands), it can be bonded. The adhesive shall be gradually bonded from one side to the other, and then pressure shall be applied from the middle to the edge to remove air and prevent bubbles. In order to achieve a better bonding effect, 2kg force shall be applied to roll up or knock 2-3 times after bonding, and the best effect shall be achieved after 24 hours at room temperature.

[Precautions]: 1. This product contains volatile solvent. Keep the air clear when using it. Do not approach open fire, swallow it, or let children touch it.

2. The moisture content of plates shall not be higher than 5%.

3. This product should not be used in direct sunlight or places where the temperature exceeds 120 ℃. (Suitable temperature - 10 ℃ to 120 ℃)

4. New materials that have not been used should be used in a small area before use, and can only be used after the product quality is approved.

5. If dilution is required, it can be diluted with the company's special thinner.

6. Please follow the manufacturer's instructions for safe use. Our company will not be responsible for any accident caused by unauthorized use.

Shelf life: 12 months

Specifications: 18L, 3L

Executive standard: GB18583-2001 Q/VAHH2-2006 Limit of harmful substances in rubber solvent adhesive:

Product description: This product adopts the latest formula, uses new polymer materials, and is a new generation of products produced by special processes. It has high bonding strength, fast drying speed, easy painting, good durability, good cold resistance and moisture resistance, even glue without precipitation, excellent quality and superior quality.

Application: It is applicable to the self adhesion and mutual adhesion of aluminum plastic plate, wood, fireproof plate, paint free plate, bamboo plate, Baoli plate, PVC plate, sponge, ceramics, carpet material, hard plastic plate, rubber, general leather, stainless steel plate and various metal materials.

Usage: The two surfaces of the adherend must be clean and dry, and oil stain is strictly prohibited; Evenly brush the glue solution on the two bonding surfaces (shake well when using), which can be kept constant (180-230g/m 2). Leave it in the air at room temperature for 5-30 minutes. In a cold and damp environment, extend the time appropriately. After the glue solution is in a dry film shape (it is better not to stick hands), it can be bonded. The adhesive shall be gradually bonded from one side to the other, and then pressure shall be applied from the middle to the edge to remove air and prevent bubbles. In order to achieve a better bonding effect, 2kg force shall be applied to roll up or knock 2-3 times after bonding, and the best effect shall be achieved after 24 hours at room temperature.

[Precautions]:

1. This product contains volatile solvent. Keep the air unblocked when using it. Do not approach open fire, swallow it, or let children touch it.

2. The moisture content of plates shall not be higher than 5%.

3. This product should not be used in direct sunlight or places where the temperature exceeds 60 ℃. (Suitable temperature - 20 ℃ to 60 ℃)

4. New materials that have not been used should be used in a small area before use, and can only be used after the product quality is approved.

5. If dilution is required, it can be diluted with the company's special thinner.

6. Please follow the manufacturer's instructions for safe use. Our company will not be responsible for any accident caused by unauthorized use.

·Shelf life: 12 months

·Specifications: 18L, 3L

·Executive standard: GB18583-2001 Q/VAHH2-2006 Limit of harmful substances in rubber solvent adhesive:

Product characteristics:

1. One component, dealcoholized, room temperature curing silicone sealant, easy to use;

2. It has good adhesive property; When the surface temperature of the substrate exceeds 35 ℃ or the width of the adhesive strip exceeds 15mm, please use it carefully.

3. Available in black, porcelain white, gray and other colors, other colors can be provided according to customer needs.

Product use:

1. Sealing of glass, doors and windows.

2. Sealing of various decorations

usage method:

1. Clean the surface of the material to be bonded with solvent or other methods;

2. Stick adhesive tape on the parts to be protected;

3. Trim and remove the adhesive tape before curing;

Restrictions on use:

1. It cannot be used as structural adhesive;

2. This product is neutral curing;

3. It shall not be used on oily or seeping surfaces.

matters needing attention:

1. This product is widely used for caulking. It is recommended that the ratio of width (A) to thickness (B) of adhesive tape A: B should be 2:1;

2. Store in a cool and dry place. The best environment is 25 ℃ temperature and 50% humidity. If the deviation from the above environment is too large, the storage life and service life of the product will be affected.

Shelf life: 8 months

Specifications: 260ml, 300ml, 500ml (soft package), 600ml (soft package)

[Note]: Do not let children touch. If the eyes directly contact the uncured adhesive, wash them with plenty of water and ask a doctor for help.

Responsibility statement:

The company guarantees that the products manufactured by it strictly comply with the national quality standards. However, based on the differences in construction conditions (including materials, construction methods, climate, etc.), pre-test should be carried out before use and the applicability of the products should be independently determined to meet the construction requirements. The company is responsible for the quality of the products properly stored and used within the validity period. Within this scope, if the products do not meet the quality requirements, customers can replace the products. In addition, the Company shall not assume any other direct or indirect responsibility. The company provides technical support for products, and can contact the dealer or the company.

Product description: This product is a kind of one component acid glass adhesive, widely used, durable, low modulus silicone sealant. When using, the thickness of the adhesive strip is greater than 3mm, otherwise it is easy to have quality problems.

Application: sealing of glass, aluminum alloy, ceramics, glass fiber, non oil wood, etc. For powder spraying of aluminum alloy, the wax coating must be removed with solvent.

Restricted use: This product is not applicable to structural glass assembly works, aquariums, places continuously immersed in water or wet all the year round, all materials that will exude grease, plasticizer or solvent, airtight places, copper, aluminum and galvanized metal surfaces, and cannot be used on the surface of mirrors. The user must decide the applicability of the product by himself, and the company will not be responsible for any loss caused by accident.

Product characteristics:

1. Excellent weather resistance, UV resistance, ozone resistance and water resistance.

2. No primer is required, which can produce strong adhesion to most building materials, but the surface must be clean and free of oil stain.

3. When the surface temperature of the material is lower than 5 ℃ or higher than 35 ℃, it is not suitable for construction. After curing, the temperature between - 50 ℃ and 100 ℃ remains essentially unchanged.

Shelf life: 8 months

Specification: 260ml, 300ml

[Note]: Do not let children touch. If the eyes directly contact the uncured adhesive, wash them with plenty of water and ask a doctor for help. Keep well ventilated when using. Avoid contact with skin as much as possible.

Responsibility statement:

The company guarantees that the products manufactured by it strictly comply with the national quality standards. However, based on the differences in construction conditions (including materials, construction methods, climate, etc.), pre-test should be carried out before use and the applicability of the products should be independently determined to meet the construction requirements. The company is responsible for the quality of the products properly stored and used within the validity period. Within this scope, if the products do not meet the quality requirements, customers can replace the products. In addition, the Company shall not assume any other direct or indirect responsibility. The company provides technical support for products, and can contact the dealer or the company.

Product description: This product adopts the latest formula, uses new polymer materials, and is a new generation product produced by special process. It has high bonding strength, fast drying speed, easy brushing, good durability, cold resistance and moisture resistance

Excellent performance, even glue without sedimentation, excellent quality and superior quality.

Application: It is applicable to the self adhesion and mutual adhesion of aluminum plastic plate, wood, fireproof plate, paint free plate, bamboo plate, Baoli plate, PVC plate, sponge, ceramics, carpet material, hard plastic plate, rubber, general leather, stainless steel plate and various metal materials.

Usage: The two surfaces of the adherend must be clean and dry, and oil stain is strictly prohibited; Evenly brush the glue solution on the two bonding surfaces (shake well when using), which can be kept constant (180-230g/m 2). Leave it in the air at room temperature for 5-30 minutes. In a cold and damp environment, extend the time appropriately. After the glue solution is in the form of a dry film (it is better not to stick), it can be bonded. The adhesive shall be gradually bonded from one side to the other, and then pressure shall be applied from the middle to the edge to remove air and prevent bubbles. In order to achieve a better bonding effect, 2kg force shall be applied to roll up or knock 2-3 times after bonding, and the best effect shall be achieved after 24 hours at room temperature.

[Precautions]:

1. This product contains volatile solvent. Keep the air unblocked when using it. Do not approach open fire, swallow it, or let children touch it.

2. The moisture content of plates shall not be higher than 5%.

3. This product should not be used in direct sunlight or places where the temperature exceeds 60 ℃. (Suitable temperature - 20 ℃ to 60 ℃)

4. New materials that have not been used should be used in a small area before use, and can only be used after the product quality is approved.

5. If dilution is required, it can be diluted with the company's special thinner.

6. Please follow the manufacturer's instructions for safe use. Our company will not be responsible for any accident caused by unauthorized use.

Shelf life: 12 months

Specifications: 18L, 3L

Executive standard: GB18583-2001 Q/VAHH2-2006 Limit of harmful substances in rubber solvent adhesive: